1. Material Overview

- Composition: JGS1 is a high-purity fused silica (SiO₂ > 99.99%) with a low hydroxyl content (<10 ppm), making it ideal for ultraviolet (UV) applications.

- Form: Non-crystalline (amorphous) glass with a homogeneous structure.

- Key Properties:

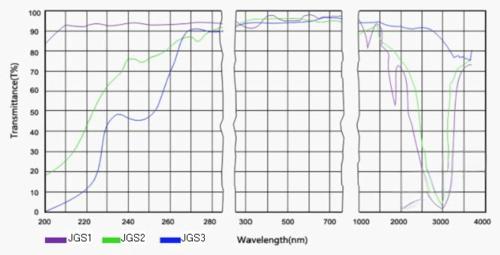

- Transmittance: Excellent from 185 nm to 2500 nm (UV to near-infrared), with minimal absorption in the deep UV range (185–250 nm).

- Thermal Stability: Low thermal expansion coefficient (≈0.55 × 10⁻⁶/K at 20–1000°C), resistant to thermal shock.

- Chemical Resistance: Inert to most acids and alkalis, suitable for harsh environments.

- Mechanical Strength: High hardness (≈6.5 Mohs) and fracture toughness.

- Electrical Properties: Low dielectric loss and high insulation resistance.

2. Optical Characteristics

- UV Transmittance: >90% at 185 nm, >85% at 200 nm, and >80% at 250 nm.

- Infrared Cutoff: ~2500 nm due to Si-O-Si bond vibrations.

- Refractive Index: ≈1.4585 at 589.3 nm (Na D-line), with low dispersion.

- Birefringence: <1 nm/cm (minimal optical distortion).

3. Thermal Properties

- Melting Point: ~1700°C (softening point: 1730°C).

- Operating Temperature Range: -50°C to 1200°C (short-term up to 1250°C).

- Thermal Conductivity: ~1.38 W/(m·K) at 20°C.

- Heat Capacity: ≈0.774 J/(g·K).

4. Physical Properties

- Density: ≈2.2 g/cm³.

- Young’s Modulus: ≈72 GPa.

- Poisson’s Ratio: ≈0.17.

- Surface Hardness: ≈550–600 HV (Vickers).

5. Chemical Resistance

- Acid Resistance: Resistant to HF, HCl, H₂SO₄, and HNO₃ at room temperature.

- Alkali Resistance: Resistant to NaOH and KOH solutions (except at high concentrations or temperatures).

- Solvent Resistance: Inert to organic solvents and water.

6. Applications

- UV Optics: Lenses, windows, prisms, and filters for UV spectroscopy and lithography.

- High-Temperature Environments: Furnace windows, observation ports, and thermal shields.

- Semiconductor Industry: Wafer carriers, diffusion tubes, and plasma etching chambers.

- Medical Devices: UV sterilization components and surgical instruments.

- Laser Systems: High-power laser windows and mirrors.

7. Customization Options

- Sizes: Available in standard dimensions (e.g., 10 mm × 10 mm × 2 mm) or custom-cut to specifications.

- Shapes: Plates, discs, rods, tubes, or complex geometries.

- Surface Finish: Polished to λ/10 or better for optical-grade surfaces.

- Tolerances: ±0.1 mm for thickness, ±0.5° for angles.

8. Quality Assurance

- Standards: Meets ISO 9001 and ASTM E490 for optical materials.

- Testing: Includes transmittance, surface quality, and dimensional accuracy checks.

- Certifications: CE, RoHS, and REACH compliant.

9. Handling & Storage

- Precautions: Avoid contact with HF or concentrated alkalis; use cleanroom gloves for handling.

- Storage: Keep in dry, dust-free environments to prevent surface contamination.

10. Comparison with Other Grades

- vs. JGS2: JGS2 has higher hydroxyl content (~220 ppm), reducing UV transmittance below 200 nm but improving IR performance.

- vs. JGS3: JGS3 is designed for IR applications (transparent up to 3500 nm).

评价

目前还没有评价