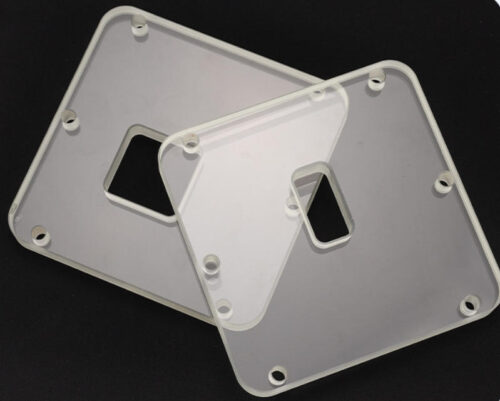

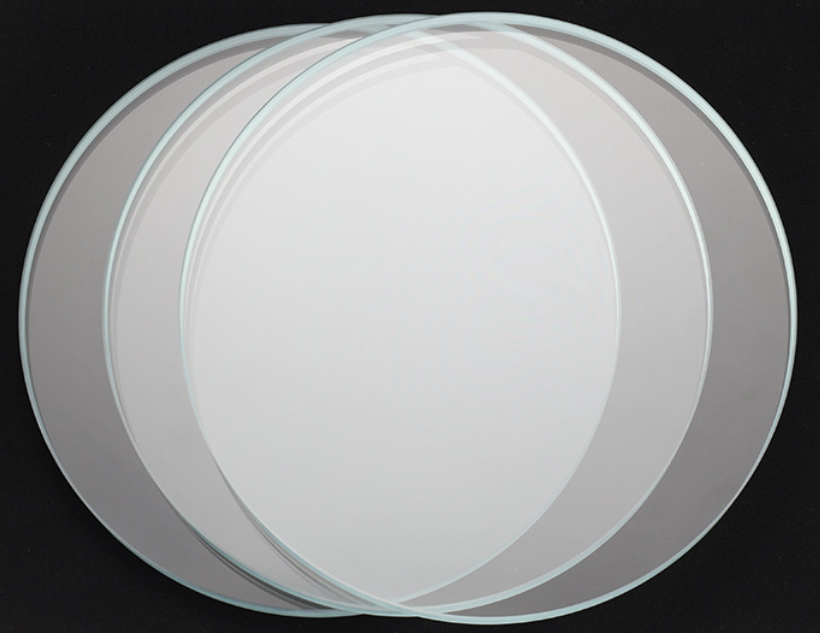

Custom-Made High Borosilicate Glass Optical Filters: A Superior Solution for Precise Light Control

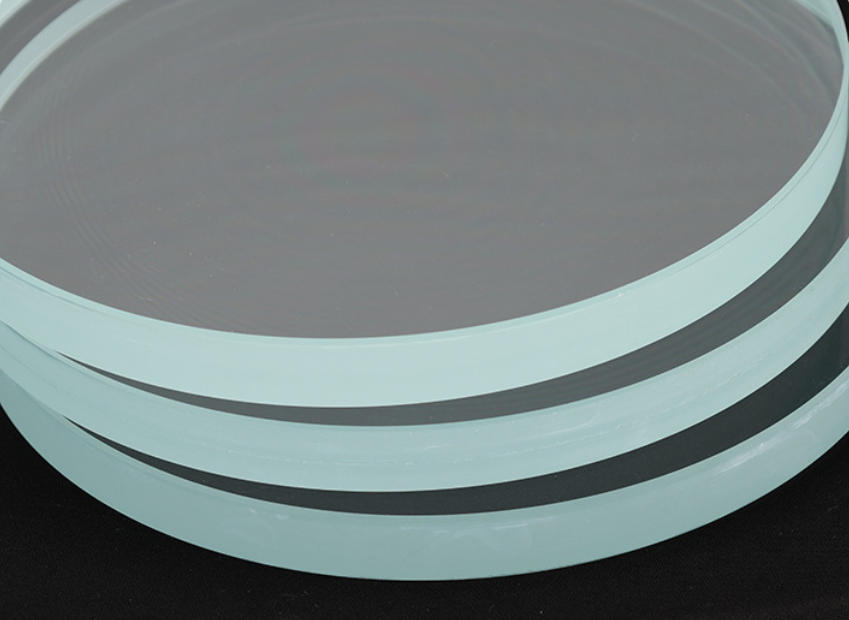

In high-precision optical applications, custom-made high borosilicate glass optical filters stand out as critical components for sensors, laser systems, medical devices, and scientific instruments, thanks to their outstanding physical and optical properties. This product is specifically designed to meet demands for wavelength selection, environmental resistance, and long-term stability, offering solutions ranging from standard to fully customized options.

Core Features and Advantages

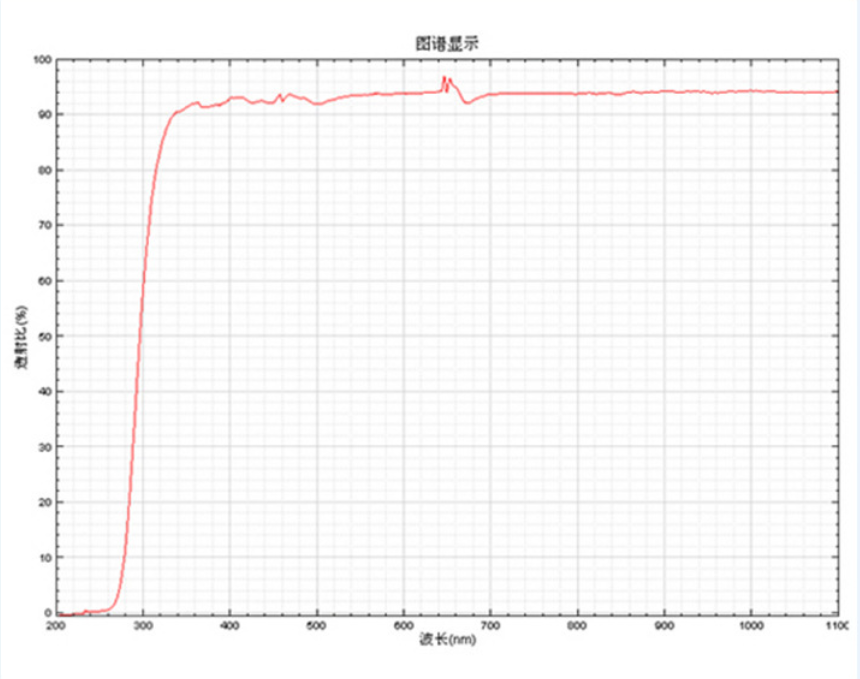

- Exceptional Optical Performance: High borosilicate glass exhibits low scattering loss and high transmittance, ensuring precise spectral filtering across the ultraviolet to near-infrared range while effectively minimizing stray light interference. Its strong chemical stability resists moisture and temperature fluctuations, making it suitable for harsh environments.

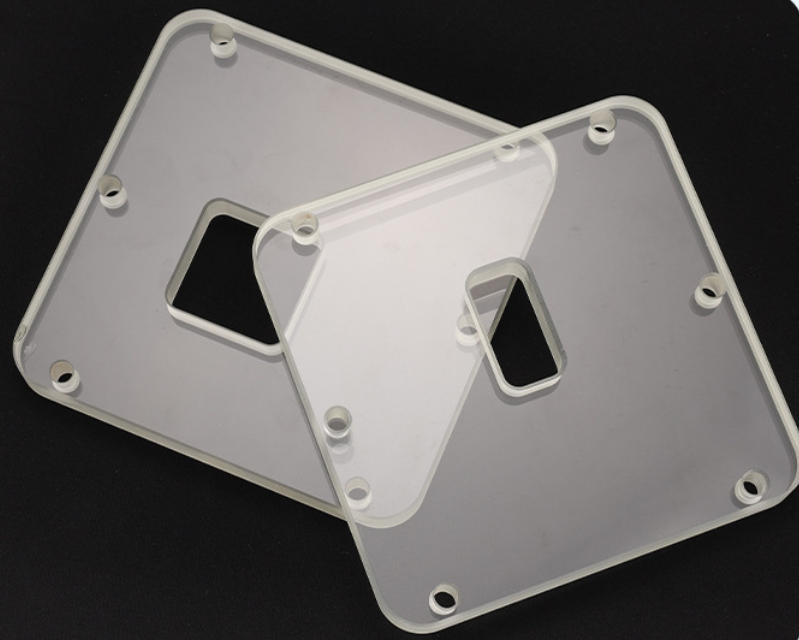

- Customizable Design: Supports on-demand adjustments to thickness, shape, and surface quality, with options to integrate specialized coatings (e.g., anti-reflective or wear-resistant layers) to enhance absorption or reflection in specific wavelength regions. For example, narrowband filters optimized for laser protection or biomedical imaging can be developed.

- Environmental and Mechanical Durability: The material offers high thermal resistance and impact strength, making it ideal for high-temperature or high-vibration scenarios, such as industrial sensors and aerospace equipment. It maintains stable performance over long-term use, reducing maintenance costs.

Application Scenarios

- Precision Instruments: Used in microscopes and spectrometers to enhance imaging clarity and data accuracy.

- Medical Technology: Filters specific wavelengths in diagnostic equipment to improve detection sensitivity.

- Industrial Automation: Integrated into environmental monitoring systems to ensure reliable sensor operation in harsh conditions.

Customization Process

- Requirement Analysis: Clients provide details on spectral range, dimensions, and functional requirements.

- Design and Validation: Advanced simulation tools optimize filter parameters to ensure compliance with application standards.

- Precision Manufacturing: High-precision processing techniques strictly control surface finish and tolerances.

- Quality Inspection: Performance is verified through tests for transmittance, temperature resistance, and other parameters before delivery.

Why Choose This Product?

- Technological Leadership: Combines material science innovation to balance optical purity and structural strength.

- Service Assurance: Provides end-to-end support from prototyping to mass production, ensuring timely delivery and post-sales optimization.

- Sustainability: The material is recyclable, aligning with environmental trends and supporting green technology development.

Whether for cutting-edge research projects or industrial systems requiring reliable components, custom high borosilicate glass optical filters offer precise performance and tailored solutions as an ideal partner for your optical needs.

评价

目前还没有评价